Introduction

In Latin America and the Caribbean, a significant digital divide is observed compared to countries that have generated and accumulated technological and institutional capacities (ECLAC, 2019). In these countries, resistance to digitization is evident, conditioned by the fear of job losses and lack of digital learning opportunities. (Barleta, Pérez, & Sánchez, 2019)

Smart ports use emerging technologies such as the Internet of Things, Big Data, blockchain or distributed ledger technologies, machine learning techniques (Du, 2023), artificial intelligence (Cho, Park, Kim, & Cho, 2021) and other methods to improve economic competitiveness, port efficiency, social, environmental and energy sustainability of operations, as well as the safety and security of facilities (Cao & Zheng, 2024). A smart port transforms its value chain into an open ecosystem (Bo & Junqing, 2020) that is interconnected in all its areas. (Fundación Valenciaport, 2020)

The port system in Colombia is structured around port concessions, which are granted by the competent authority to duly established port companies. These companies have the responsibility for building and operating ports. They may be private, public or a combination of both and their main activity is investment in the construction, maintenance and management of port facilities. As for the containerized cargo, the Port Traffic Bulletin issued by the Superintendency of Transport reports that 29.4 million tons was mostly mobilized by Cartagena with 68% (20 million tons), followed by Buenaventura with 24.3% (7.1 million tons). (Colombian Superintendency of Transportation, 2023)

The Cartagena Port Group operates two container terminals: the Cartagena Regional Port Company (Manga terminal) and the Cartagena Container Terminal (CONTECAR). However, the focus of this study will be on CONTECAR, considered the most technologically advanced terminal in the country and nationally recognized for its innovations in port operations.

The Cartagena Port Group is constantly working on research and development of new technologies that optimize operational efficiency and strengthen the connection with its customers and consumers. Its main objective is to improve the integration of the logistics chain at a global level, ensuring more agile, secure and competitive processes.

Based on the collection of data on the processes of container entry and exit in CONTECAR, a SWOT analysis was carried out to identify strengths, weaknesses, opportunities and threats associated with current operations. This analysis aims to ensure that the proposed model is adapted to the needs and available resources, avoiding high investment costs.

Through a literature review, cases of international maritime terminals that have implemented deep learning systems in their operations were identified, focusing on the use of this technology for non-intrusive inspection of containerized cargo. This allowed a better understanding of the applications of deep learning in port activities and to define the conditions and resources necessary for the design, development, implementation, control and monitoring of image analysis software.

The research, which was of a mixed approach, combined semi-structured interviews and bibliographical review. To characterize the operations of CONTECAR, synchronous interviews were conducted through Teams, supplemented by forms on Microsoft Forms, addressed to three experts in terminal operational processes. At the same time, the literature review facilitated the identification of technologies used in other international ports that could be adapted to the local context of CONTECAR.

Exploratory in nature, the research is based on previously applied bibliography and models, which enables the adaptation of innovative solutions to the terminal environment.

The document is structured in four main sections. The first one presents basic concepts on deep learning and OCR, as well as examples of their application in national and international port terminals. The second part addresses the current process of container entry and exit in CONTECAR, available technologies and a SWOT system analysis. The third section details the hardware and software requirements for implementing a deep learning-based model with OCR technology. Finally, the conclusion integrates the data collected and presents a proposal to optimize the process of entering and leaving containers in CONTECAR, along with the required investment.

Materials and methods

Methodology

The research adopted a mixed approach combining qualitative and quantitative methods, allowing for a comprehensive analysis of technical, economic and operational data. This approach facilitated the interpretation of results and their applicability in the port sector. An exhaustive review of the scientific literature on the use of deep learning in image analysis was conducted, with emphasis on the processes of container entry and exit at advanced technology port terminals.

To complement the analysis, perspectives from experts in port operations in Colombia were considered, whose viewpoints provided key insights on challenges and opportunities in the implementation of deep learning in the sector. Data collection was carried out through questionnaires with open, closed questions and Likert scales, as well as structured interviews by e-mail. This provided detailed information on the needs of the sector and its technological transformation.

Type of research

Given the scarce bibliographic material in Colombia on deep learning in the port sector, exploratory research was conducted to identify challenges, opportunities and limitations in the automation of containers entry and exit processes. In addition, a descriptive approach was adopted to detail the technical, operational and economic requirements of the proposed model, based on international case analyses and data collected from interviews and official documents.

Target population

The research was framed in a particularist ethnographic paradigm, with a sample of six experts in port operations in Colombia. Four of them completed questionnaires by email, while two participated in online interviews using Microsoft Teams and filled out a form on Microsoft Forms.

Stages of research

The methodology was structured in three phases:

Conceptualization and design:

An exploratory review of the processes of entry and exit of containers in Colombian terminals and of the tools of Logistics 4.0 implemented was carried out. Technologies such as optical character recognition (OCR) and deep learning were analyzed to assess their impact on port modernization.

Research Instrument

For data collection, a questionnaire with open-ended, closed-ended and Likert scale questions was used, as well as semi-structured interviews. The confidentiality of information was guaranteed by informed consent, in compliance with the legislation in force in Colombia (Art. 18 Law 1712 of 2014).

The questionnaire, designed in Microsoft Forms, included 25 questions divided into three sections:

Characterization of the processes of container entry and exit.

Assessment of the use of OCR technology in port terminals.

Analysis of the deep learning potential in port automation.

These questions allowed us to identify strengths, weaknesses and opportunities for improvement in the implementation of advanced technologies at Colombian port terminals.

Results and discussion

1. International and National Technological Background

In artificial vision, deep learning allows images and videos to be analyzed for tasks such as classification, object detection (Zhou & Wang, 2024) and semantic segmentation (Hirata, Watanabe, & Lambrou, 2022). Its applications range from the detection of manufacturing defects (Licu, 2020) to the identification of tumors in radiology and the improvement of safety in automobiles by advanced driver assistance systems (Jaccard, Rogers, Norton, & Griffin, 2016). In addition, in retail, it facilitates visual searches and personalized recommendations, improving the customer experience. (Holdsworth & Scapicchio, 2024)

The accelerated development of deep learning (DL) has allowed significant advances in port terminals (Wang, et al., 2024), particularly in container number recognition technology. This technology has reached a high degree of maturity, offering precise and efficient solutions for container identification in various operating conditions. (Tang, Chen, & Li, 2020)

Optical character recognition (OCR) is a key technology in digital transformation, defined by Amazon as a process that converts text images into a machine-readable digital format (Cimili, Voegl, Hirsch, & Gronalt, 2022). For example, when scanning a form or receipt, the result is an image that cannot be edited or searched in a text editor, but thanks to OCR, it can be converted into an editable document that can be used in various applications (Cho, Park, Kim, & Cho, 2021). In the logistics sector, OCR improves traceability of labels, invoices and documents, reducing errors and increasing productivity. Companies like Foresight Group have integrated this technology to automate invoice processing in accounting systems, eliminating manual processes and optimizing the operation. (Amazon, 2025)

Optical Character Recognition (OCR) plays a crucial role in optimizing port operations, especially in container terminals, where its implementation significantly improves the visibility of assets, operational control, safety and security (Carlan, Sys, Calatayud, & Vanelslander, 2018). This technology has transformed key processes by automating tasks that previously required manual intervention, facilitating efficient operations management in complex logistics environments (Vaca-Recalde, et al., 2024).

Despite their advances, traditional OCR systems face significant challenges in ports due to specific environmental conditions. Factors such as angle limitations when capturing images from containers and the diversity in font styles used in labels create problems like skewed text or overlay characters. These difficulties negatively affect the accuracy of the recognition, which represents a challenge to maintain efficiency and reliability in the flow of operations. (Rubio Villalba, 2020)

Overcoming these obstacles requires the development and integration of advanced technologies, such as deep learning algorithms that allow for greater adaptability to changing port conditions and improve recognition rates in complex operating environments. (Zhichao, Yi, Rui, & Kaimin, 2024)

1.1. International Background

The Port of Bilbao, one of the main multimodal centers in northern Spain, implemented OCR-based technology to automate real-time tracking of goods. This system, installed in the access lanes, allows key information to be captured from containers, vehicles and wagons, even under adverse conditions. With the elimination of manual checks, operational efficiency was optimized, reducing waiting times, fuel costs and polluting emissions, consolidating the port as a benchmark in technological innovation and efficiency in the sector (Telefónica, 2025).

The Port of Barcelona, known for its high container handling capacity, faced challenges in the precise identification of containers and wagons due to the variable code conditions. To solve it, installed cameras and lighting systems on the railway tracks, achieving 99% accuracy in asset identification. This system significantly improved traceability and automated control, without the need for additional infrastructure, optimizing logistics processes and increasing efficiency in the flow of goods. (Consorcio Siport21, 2025)

The Port of Algeciras, Spain’s main port in traffic volume, implemented an advanced OCR system to improve vehicle and goods identification. With a lightweight and easy to install system, it achieved 97% accuracy in real-time identification. The solution covered 24 control points and allowed the monitoring of previously unmonitored lanes, optimizing traceability and reducing operating costs, strengthening the port’s competitiveness in the international arena. (Port Authority of the Bay of Algeciras, 2023)

1.2. National Background

The Buenaventura Container Terminal uses OCR technology for character reading at the entrance and exit of the terminal, as well as before the container scanner. This technology allows the reading of vehicle plates and ISO codes on containers. However, despite the existence of OCR technology for loading and unloading ships, it is not yet implemented in these operations within the terminal.

The Santa Marta Port Corporation uses OCR technology to read container numbers using scanners, although it faces challenges in integrating scanner software with terminal operating system (TOS). In addition, there are problems with the accuracy of container reading and slow integration of different systems, which affects operational efficiency. The president of the Santa Marta Port Society, engineer Chinea, highlights the need for a comprehensive implementation of OCR technology to avoid operational inconsistencies.

The Barranquilla Regional Port Society does not yet use OCR technology, but is exploring its implementation using high-resolution cameras and artificial intelligence software. This solution allows data such as container numbers, vehicle registration and truck characteristics to be detected in a cost-effective, adaptable and easy to integrate with terminal operating systems, which promises to optimize port operations.

2. Operational and technological characteristics of CONTECAR in its process of entering and leaving containers

According to the information published on the terminal’s website: "Thanks to its infrastructure and equipment, operated by highly qualified employees, the Cartagena Port Group has been recognized many times as the best port in the Caribbean. Its high international standards allow it to offer highly efficient services" (Grupo Puerto de Cartagena, 2025)

(Aguirre Olmos, 2018) In CONTECAR the control of operations is highly automated, port clients interact mainly through the Web Service called SPRCOnline. Taking into account the type of client of the port (Carrier, exporter, SIA, among others), you have access to services that they may require.

According to the experts interviewed, the terminal has most of the technological resources and infrastructure necessary to facilitate the implementation of a deep learning model in the processes of entering and leaving containers. In addition, the senior management of the terminal shows a positive disposition towards the adoption and implementation of new technologies that optimize process efficiency.

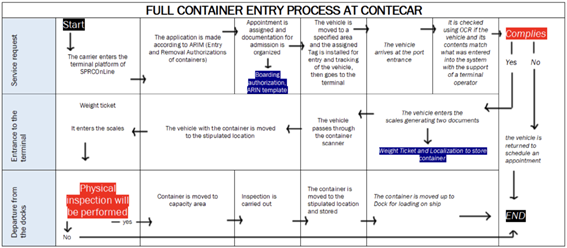

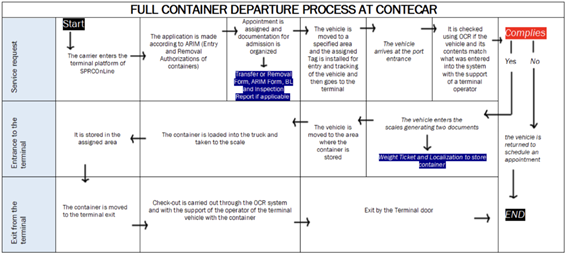

2.1. Process of container entry and exit in CONTECAR

For the entry of trucks to the terminal, it is essential that the corresponding authorizations for the entry and exit of cargo are duly marked in ARIM formats (Authorization of Entry and Withdrawal of Containers). These records must include accurate information about the driver, ID number, license plate, and type of truck. All these data must be updated on the port terminal’s SPRCOnLine digital platform.

The SPRCOnLine system allows users to make necessary modifications to existing authorizations. This includes updating driver-related data such as: a. Driver ID number, b. Driver’s name, c. Truck license plate number, d. Truck type.

The update procedure is carried out in a simple way through the platform, and allows to generate a confirmation document that validates the changes made. In addition, updated authorizations can be viewed and printed, including both ARIM and empty container entry and removal authorizations. (Cartagena Port Group, 2025)

2.2. Flow of Operations in the Port

1. Preparation and tag assignment (container tracking system based on RFID):

Carriers program vehicles in advance in a specific area, where the ARIM tag is installed. The truck must wait its assigned shift and time to enter the port terminal.

2. Entry into port:

Sensors detect the vehicle tag when you arrive at the entrance. Driver information (name and ID), vehicle (type and plate), container, and tag are verified in the system. Once the information is validated, the vehicle accesses the scale.

3. Process within the port:

On the scale a ticket is generated with the weight and location assigned, either to load or unload containers. The vehicle passes through a scanner for additional verification and then heads to the assigned area. Throughout its movement within the terminal, the truck is monitored by strategically installed sensors that track the tag.

4. Departure from port:

After the operation is completed, the vehicle returns to the scale and then proceeds to the exit gate. Security staff checks the documentation and tag again before completing the process.

2.3. SWOT analysis of the process of entering and leaving containers in CONTECAR

To evaluate the current status of the process of container entry and exit from the port terminal CONTECAR, a SWOT analysis (Weaknesses, Opportunities, Strengths and Threats) was applied, as it allows to assess the internal and external factors affecting the process (Figure 1). This matrix provides a detailed analysis of the opportunities and threats in the environment, as well as the internal strengths and weaknesses that influence your operations. Through this analysis, strategies are sought that maximize opportunities, minimize threats, strengthen internal capabilities and address weaknesses (Table 1). This holistic approach is critical to improving operational efficiency, optimizing logistics processes and ensuring a sustainable competitive advantage in the port sector (Table 2). The main variables identified and recommended strategies to boost the efficiency of container entry and exit in CONTECAR are detailed below.

Table 1

SO and ST strategies of the container entry process in CONTECAR

Table 2

WO and WT strategies for the container entry and exit process

3. Technological, Physical Infrastructure Requirements Necessary for the Implementation of a Deep Learning Model

3.1. Technologies implemented by CONTECAR

The Cartagena Container Terminal (CONTECAR) has been implementing significant technological advances in its operation, aligning itself with the trends of the fourth industrial revolution. As presented in its 2023 management report and on the website, these advances include the digitization of processes, the use of exponential technologies and the creation of a collaborative environment that improves operational efficiency, within the digitization of processes including the adoption of optical character recognition (OCR) technology, which improve safety and efficiency in their operations. This system would allow for automation of access control and container identification, which is crucial to meeting international safety standards.

SPRCOnLine: SPRCOnLine is a digital platform implemented by CONTECAR to efficiently manage entry and exit authorizations for trucks. It enables data updating, document validation and record automation, which optimizes the vehicle flow and improves traceability and control of operations. It also uses RFID technology (Li, Zhuang, Yang, Wenran, & Xu, 2024) to monitor truck entry and exit, reducing errors and bottlenecks when scheduling shifts and schedules, and contributing to a more agile and efficient operation within the port.

WhereTAG: The WhereTag is an RFID device assigned to trucks for identification and tracking within CONTECAR. This device records the passage of trucks through checkpoints, such as portals and scales, and is essential for logistics operation. It is managed through SPRCOnLine, where devices are assigned and unassigned to vehicles according to active authorization documents, ensuring traceability and control during loading and unloading operations.

Information and physical security systems: Since 2012, CONTECAR has used the IBM TIVOLI system for infrastructure monitoring and information security. However, in 2023, it implemented DYNATRACE, an advanced cloud-based platform that uses artificial intelligence to monitor the health and performance of technology assets and systems. This tool optimizes the management of technological resources, improves operational safety and ensures the continuity of port services, representing an important step in the modernization of the terminal’s technological infrastructure.

3.2. Technologies Required to Implement a Deep Learning Model

The implementation of deep learning-based optical character recognition (OCR) technologies on the CONTECAR port would optimize container management by automating reading alphanumeric codes and relevant data, Improving traceability and control of their movement. Modern OCR systems, supported by neural networks, process images in real time even under adverse conditions, reducing human error and increasing operational safety.

Integration with existing management systems is essential to maximize its impact, requiring rigorous technical evaluation and the use of specialized hardware such as high-resolution cameras and optical sensors. In addition, collaboration between experts in artificial intelligence and port operations ensures effective implementation.

The minimum technical requirements necessary for the implementation of this technology are (Table 3):

Table 3

Minimum requirements to implement Deep Learning model with OCR

For the most suitable cameras, it will depend on the customer’s use case, the distance from the camera to the reading object and the focal length of the camera (Table 4).

Table 4

Recommended cameras for Deep Learning model with OCR

3.3. Model of Input and Output of COUNTERS with Implementation of Deep Leaning

Implementing an OCR system with deep learning would optimize container management, increasing automation and process accuracy, reducing errors and improving operational efficiency. To ensure its performance, it is required to meet certain minimum hardware standards. In this context, and considering the operation of two entry and two exit lanes, a technical proposal was developed as shown in charts 1 and 2, based on an updated market quote as at January 2025, designed to meet the operational and economic demands of the port.

3.4. Model Costs and Investment

Technical evaluation ensures that the selected hardware has the capability to process data in real time and integrate efficiently with existing infrastructure. The proposed components achieve a balance between cost and performance, ensuring the reliability of the OCR system even under adverse conditions such as constant vehicle flows and environmental variations. This approach strengthens the port’s competitiveness and optimizes the use of its technological resources.

The following are listed resources, whose values are expressed in US dollars (USD) (Table 5):

Table 5

Hardware resources required to implement the model

In the case of listed software, it is an application acquired through a technical license with a duration of one year. This license includes deployment, which is estimated to take approximately 4-6 months, provided that the hardware is pre-installed and available. It is important to mention that the implementation time may vary according to the number of checkpoints, with an average of 2 months per point. The license also provides for monitoring and technical support throughout its life.

It should be noted that prices vary according to the number of checkpoints (monitoring cameras). Based on the above, the estimated price for the 4 control points, distributed in 2 cameras at the entrance and 2 at the exit door, was as follows (Table 6):

Table 6

Software resources required to implement the model

| RESOURCES | AMOUNT | COST PER UNIT | TOTAL COST |

|---|---|---|---|

| OCR Application with deep learning involvement | 4 | $ 10.424 | $ 41.698 |

| $ 10.424 | $ 41.698 |

The total investment, if necessary to purchase hardware, is $9,332. The cost of software and technical support is $41,098, for a total of $51,030. It is important to note that the investment in hardware would only be made during the first year, as detailed below (Table 7):

Table 7

Total investment in Hardware and Software

| Resources | Amount | Total cost |

|---|---|---|

| Hardware | 1 | $9.332 |

| Software | 1 | $41.698 |

| $51.030 |

The implementation of OCR technology at the port of CONTECAR represents an opportunity to optimize processes, reduce operating costs and increase efficiency in container management. Currently, the port operates with two 24-hour entry and two exit lanes, with four operators in charge of validating appointments and verifying key information on vehicles, containers, drivers and tags before authorizing access.

The analysis of operating costs, based on the minimum wage in force in 2025 and excluding surcharges or bonuses, allows to assess the economic impact of this technology. By automating these tasks, the OCR system would not only reduce personnel costs but also increase accuracy and agility in operations, strengthening port efficiency and competitiveness (Table 8).

Table 8

Calculation of the cost of the salary of door operators in CONTECAR without OCR

The implementation of OCR technology at the port allows to optimize the processes of entry and exit of vehicles by automating the verification of information. This innovation reduces the operational burden on staff, allowing for their relocation and reducing the staffing of two to one operator per rail. As a result, a 50 per cent reduction in personnel costs is achieved while efficiency is improved and port operations are strengthened (Table 9).

Table 9

Calculation of the cost of the salary of door operators in CONTECAR with OCR

| COST CALCULATION | |

|---|---|

| Cost per worker Monthly | $ 573 |

| Total port operators per approximate month | 12 |

| TOTAL COST PER WORKER MONTHLY | $ 6.876 |

| Months in the year | 12 |

| TOTAL ANNUALIZED COST | $ 82.512 |

Generating the following difference in the operation (Table 10):

Table 10

Cost comparison

| CONCEPTS | COSTS |

|---|---|

| Annualized total cost (without OCR) | $165.024 |

| Annualized total cost (with OCR) | $82.512 |

| Reduction in operational costs | $82.512 |

Two possible options are presented to take advantage of the cost reduction and maximize the return on investment, considering that in the second year it will not be necessary to make the same investment in hardware for the operation of the application. This will allow for a higher return on investment in a shorter time in the years to come (Table 11).

In this analysis, Year 1 takes 2025 as a reference point, while Year 2 corresponds to 2026, without considering wage increases or adjustments in software costs.

Table 11

Annual model return on investment

The analysis of the Table 12shows a return of 162% in the first year and 198% in the second year, taking as reference the initial investment, which can be amortized within one year. Thus, a monthly profit of $2,623usd and an annual one of $31,482usd will be generated in the first year, while in the second year the monthly profit will be of $3,401usd and the annual one of $40.814 usd.

Table 12

Return on investment in months

| 1st year | 2nd year | |

|---|---|---|

| CONCEPTS | COST | COST |

| Costs of OCR implementation | $ 51.030 | $ 41.698 |

| Reduction in cost and | $ 6.876 | $ 6.876 |

| Return time in months | 7,42 | 6,06 |

The analysis of implementation costs, considering their coverage with monthly generated profit, indicates that the return on investment would be achieved in approximately 7 and a half months during the first year, and 6 months in the second year.

Conclusions

According to the SWOT analysis, it was identified that although Cartagena Container Terminal -CONTECAR has an efficient process of entering and leaving containers supported by RFID technology and a centralized information system, there is an opportunity for significant improvement by integrating a deep learning model based on the OCR technology available in the terminal, but currently not used.

The main advantage of using neural networks is their ability to process raw pixel data, autonomously extracting key features and classifying them. This allows for greater accuracy in data analysis. However, an unfavorable aspect of Deep Learning models is their high investment cost compared to alternative methods such as template matching and statistical feature extractors (Shashirangana, Padmasiri, Meedeniya, & Perera, 2020).

Nowadays, OCR technology based on deep learning represents a significant opportunity for process optimization. In this context, the full implementation of this technology at the CONTECAR terminal would allow to speed up the attention times on entry and exit of vehicles, reducing them by up to 50% and reaching an accuracy of 98.7% (Weihong & Jiaoyang, 2020) in data capture. In addition, it should be considered that during the entry verification process 90% of vehicles remain on, increasing CO emissions. Reducing the reception times would not only reduce this environmental impact, but also optimize operational resources, achieving a 50% reduction in personnel costs and generating a $31,482 USD profit in the first year, with an estimated increase of 30% in the second.

To ensure these benefits, it is essential to assess the suitability of hardware, software and locational fit-out providers. The implementation process in the case of the CONTECAR terminal could be extended up to two months per point, and during this period all associated costs should be considered. Benefits will begin to materialize once the technology is fully operational.